Product

GuanChao’s quality, recognised worldwide.

Angle belt conveyors are intended primarily for the transport of piece goods where there is a need to change the elevation angle of material flow or the individual levels of material flow. The Guanchao angled belt conveyor applies the advanced technology of a low-tension driving belt to smooth the merging or diverging of cargo between two conveyors and to minimize the accumulated heat on the angle bar, thus increasing the durability of the belt.

The Guanchao angled belt conveyor is driven by its bottom side contacting a heavy-duty lagged drive roll. Contamination on the belt surface does not affect the conveyor operation because the drive roll contracts the bottom side of the belt. A spring-loaded take-up roll automatically maintains even belt tension even through changes in loading and temperature.

Angled belt conveyors facilitate the merging or splitting of two conveyor lines smoothly and efficiently.

Angled belt conveyors are available in airless angle bar versions for low- and medium-speed or intermittent high-speed operation, as well as airless angle bar versions for heavy-duty applications or high continuous speeds.

Angle belt conveyors are designed for merging or distribution operations. These two different types of inclined belt conveyors differ in the number of rollers and their positions. The consolidated device cannot later be converted to operate as a distributed device. Distributed angled belt conveyors generally have a longer minimum length than consolidated angled belt conveyors. Check factory-specific conveyor widths for minimum lengths and merge/distribution configurations.

A polished steel bar is used on the angled end of the conveyor. The fixed-angle bar is used to ensure even belt tracking. The China angled belt conveyor may be positioned with the angle bar as close as 4mm from the adjoining conveyor. Angles of 30° and 45° are available.

The drive lagged, which includes a 152mm diameter (medium size) and a 203mm diameter (thick size), is molded onto the steel roll and machined to provide a high friction surface.

GUANCHAO angled belt conveyors apply advanced technology of low-tension driving belts to realize the smooth merging or diverging of cargo between two conveyors and also to minimize the accumulated heat on the angle bar, thus increasing the durability of the belt.

-No need for compressed gas

-Spring take-up tension system

-Whisper quiet operation

-30° or 45° angles

-Smooth positive angular transfer of products

-Simple belt tracking system

-Easy maintenance

-Heavy duty steel construction

-Transfers small products

The China angle belt conveyor is a type of assembly line. The angled belt conveyor is used to save labor and improve work efficiency. Light products can also be used for commodity transportation at supermarket cash registers, which are widely used.

Angled belt conveyors are primarily used to transport individual items of various properties, especially where height changes are required in the material flow (for example, when products are being transported to machine warehouses). Under certain conditions, diagonal conveyors can also be equipped with C-drives with inline gears or CTRs with roller drives.

Angled belt conveyors (consolidators, V-belt conveyors) are used as part of a baggage conveying system to move baggage items onto and off conveyor sections. The lead-in and out-feed angles are set to 30° or 45°. It is ideal for airport baggage conveyors and transport systems. Reliable operation is guaranteed through its optimum power transmission capability. The device is also compatible with sorting, order picking, distribution, and transport structures.

Tank installation

The all-steel welded structure, the sides of the tank body, and the sliding bed are made of a 3MM thick iron plate, and the lower side of the tank body has a 25MM wide external flange to connect with the bracket feet.

Tank height

| tank height | Standard conveying surface width range | Optional conveying surface width range | |

| Medium tank | 216MM | 610~1041MM | 965~1524MM |

| High tank | 305MM | 1041~1600MM | 990~1600MM |

Angle bar

The angle rod is made of polished iron and is installed at a fixed angle. An angle rod with a diameter of 48 is used. Its function is to ensure that the belt will not deviate. The nearest position of the angle rod on the two adjacent conveyors is 4 mm. The angle bars of the angled belt conveyor are divided into 30° and 45° series.

| Standard-angled belt conveyor | |

| Conveyor belt | Two layers of black fiber flame-retardant tape |

| Manufacturer Part Number | E 12/2 0/U2 MT-G-SE |

| Conveying surface | black polyurethane |

| Thickness | 1.8MM |

| Allowable working tension | Width 12N/MM (1% elongation) |

| Underside | low friction fabric |

| Belt fabric | Two layers of polyester |

| Fire-proof level | DIN EN 20340 |

| Conductivity | Antistatic |

| Ambient temperature range | -30~100℃ |

| Interface | seamless interface |

Belt drive system

The belt driving principle is that the driving reel with friction surface contacts the bottom of the belt to drive the belt to run, so the accumulation on the belt surface will not affect the driving effect, and the contact angle between the belt and the driving reel can reach 210 degrees. Therefore, the belt tension must be relatively small. In addition, the spring-loaded belt tension system keeps the belt tension from being affected by load and temperature changes.

Head and tail wheel, elastic and brake wheel

The elastic pulley and the brake pulley are made of steel pipes with a diameter of 63.5 mm and a high groove body of 89 mm. The head and tail pulleys are made of steel pipes with a diameter of 89 mm. The steel bushing is welded at both ends after processing. The normal installation position of the head and tail pulleys is that the front is flush with the groove body. Generally, the belt tension is not changed by adjusting the position of the head and tail pulleys.

Drive reels and shafts

The steel bushings are processed and welded at both ends; the drive is covered with rubber, cast on the steel roller, and processed to reduce surface friction. The material of the roller shaft is S45C steel that has been turned, ground, and polished. Each axle is matched to the drive roller.

| Roller diameter | Gear ratio: 1rpm | Shaft standard diameter | |

| Medium tank | 152MM | 499MM | 30 OR 35mm |

| High tank | 203MM | 658MM | 35 OR 45mm |

Roller bearing

The drive and head and tail pulleys are precision rated, permanently sealed, and housed in a cast iron flanged housing, bearing housings with grease nipples, and both tensioner and brake pulleys with internal bearings.

Side panel

Made of a standard 3MM thick iron plate, if the side plate is higher than 150MM, there will be a 25MM outwardly angled flange at the top; the distance between the left and right plates is 76MM more than the belt width; and the end flange is standard.

Paint

After sanding, the EPOXY powder coating treatment, using various colors in the RAL series, can be matched as required.

Drive

Various series of gear motors from SEW NORD SUMITOMO are available for selection. If you purchase gear motors by yourself, our torque arm, drilling, and drive shaft openings are all standard diameters.

Confluence / Divide

The angle belt conveyor is specially designed for the application of merging and diverting. The number of rollers and the position in the fuselage of the merging machine and the diverting machine are different, so the use of the merging machine and the diverting machine is different. Interchangeable; generally, the shunt machine is longer than the fuselage of the confluence machine.

Specification example

The standard specification representation is as follows: 1060AXH1900-45 LHM

1060 represents the width of the conveying surface (the distance between the side plates);

AX means airless angle rod.

H means high rack;

1900 represents the centerline length.

45 represents the stick angle.

LH represents the running direction of the cargo after passing through the angle bar (right diversion is represented by RH);

M means that the angle bar is at the outlet end of the converging belt conveyor (the diverting conveyor is denoted by D);

Angled belt conveyors, also known as inclined or cleated belt conveyors, are specialized conveyor systems designed to move materials or products at an incline or decline. These conveyors find various applications across industries due to their ability to transport goods between different elevations efficiently. Here are some notable applications of angled belt conveyors:

In summary, angled belt conveyors offer a versatile solution for industries requiring the efficient movement of materials or products between different elevations. Their ability to handle inclines and declines makes them valuable assets in optimizing workflow, improving productivity, and facilitating the seamless transfer of goods across various sectors.

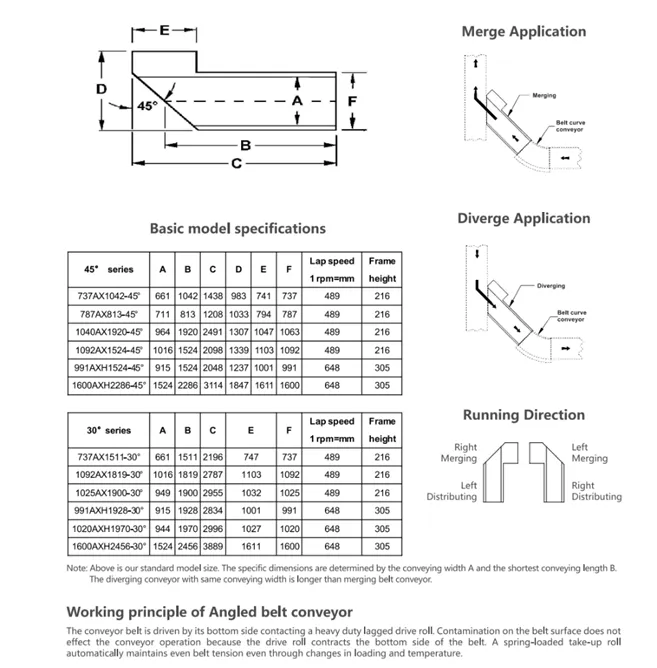

Basic model specification

|

45° series |

A | B | C | D | E | F |

Lap speed 1 rpm=mm

|

Frame height

|

|

330AXL788-45° |

254 | 788 | 981 | 569 | 341 | 330 | 329 | 178 |

|

686AXL965-45° |

610 | 965 | 1336 | 925 | 696 | 686 | 329 | 178 |

|

737AX1042-45° |

661 | 1042 | 1438 | 983 | 747 | 737 | 489 | 216 |

|

1092AX1524-45° |

1016 | 1524 | 2098 | 1339 | 1103 | 1092 | 489 | 216 |

|

991AXH1524-45° |

915 | 1524 | 2048 | 1237 | 1001 | 991 | 648 | 305 |

|

1600AXH2286-45° |

1524 | 2286 | 3114 | 1847 | 1611 | 1600 | 648 | 305 |

|

30° series |

A | B | C | E | F |

Lap speed 1 rpm=mm

|

Frame

height

|

|

330AXL945-30° |

254 | 945 | 1279 | 341 | 330 | 329 | 178 |

|

686AXL1253-30° |

610 | 1253 | 1895 | 696 | 686 | 329 | 178 |

|

737AX1511-30° |

661 | 1511 | 2196 | 747 | 737 | 489 | 216 |

|

1092AX1819-30° |

1016 | 1819 | 2787 | 1103 | 1092 | 489 | 216 |

|

991AXH1928-30° |

915 | 1928 | 2834 | 1001 | 991 | 648 | 305 |

|

1600AXH2456-30° |

1524 | 2456 | 3889 | 1611 | 1600 | 648 | 305 |

Note: bove is our standard model size. The specific dimensions are determined by the conveying width A and the shortest conveying width B. The diverging conveyor with same conveying width is longer than merging belt conveyor.

Angled Belt Conveyor

The standard specification representation is as follows: 1060AXH1900-45 LHM

1060: conveying surface width (distance between side plates)

AX : airless angle rod

H :high rack

1900 : the centerline length

45 : angle of angle-bar

LH : the running direction of the cargo after passing through the angle bar (right diversion is indicated by RH)

M : the angle bar is at the outlet end of the Confluence belt conveyor (the diverting belt conveyor is denoted by D)

: Guanchao is a leader in the logistics and transport equipment industry in China and has provided quality products for many logistics industries around the world, such as “curved belt conveyor, angled belt conveyor, telescopic conveyor”. We aim to become the world’s leading company in the logistics and transport equipment industry.

: Telescopic Conveyor/Curved Belt Conveyor/Angled Belt Conveyor/Spiral Belt Conveyor/Smart Warehouse

: Located in Nanjing, Jiangsu Province, Guanchao is an enterprise mainly engaged in research and experimental development. It has a factory area of about 60,000 square meters and two factories, located at No. 26 Zhongxing East Road, Lishui Industrial Zone, Nanjing (Nanjing Guanchao Industrial Automation Co., Ltd. was established in 2006) and No. 1 Kaiping Road, Dongping Town, Lishui, Nanjing.

: Pls contact us through:

* Inquiry module in our website

* E-Mail: Coco@gclogisticstech.com

* Phones marked in the website contact page

: We have telescopic conveyors, curved belt conveyor, angled belt conveyor, spiral belt conveyor. We will get back to you promptly with a quote for these products.

: We have professional QC team to trace each production course and ensure the product quality from parts fabrication to final completion. We will provide the quality qualified document before delivery. The third party inspection and certificates company could also be employeed as both agreement, we also welcome the client to send representative to visit our company for the course and final inspection before product delivery.

: We have standard products for telescopic conveyor, curved belt conveyor, angled belt conveyor, spiral belt conveyor, smart warehouse, as well as complex and highly customized products with delivery times between 20 and 90 days, which we will discuss with you further discussion will be confirmed in mutual communication.

: Yes, our production center is based in Nanjing. The 60,000-square-meter factory building and around 300 employees ensure the delivery of products, and new factories will be expanded later to meet a large number of potential orders.

We can deliver the complete equipment by sea. You can either use your own assigned shipping agent or our cooperative forwarder. The nearest

port is China Shanghai, Ningbo port, which is convenient for maritime transportation.

we support our business partners by after-sale service. Guanchao has many technical testing

engineers traveling world wide. Any cases would be responded with prompt solutions.

JIANGSU GUANCHAO LOGISTICS TECHNLOGY CO. LTD was set up in 2016 with a registered capital of 4.3 million dollars. Since it was established in Lishui district, Nanjing, GUANCHAO was dedicated in research, development and manufacture of whole set material conveying and handling equipment for worldwide market, such as telescopic conveyor, dynamic DWS automatic conveyor, curved belt conveyors etc.

Our core products, with its excellent extension capacity of loading unloading, professional design, flexible service customization and exquisite processing technology, have made it world first-class level and leading position in domestic industry.

Continuous exceeding! Create the world-leading telescopic conveyor!

+86 15195840178

Company Qr Code